For UK professionals in construction, engineering, and land management, the question is no longer if drones can be used for surveying, but how to guarantee the data meets rigorous professional criteria. Navigating the complex world of drone survey accuracy standards is the critical first step, yet it’s an area often clouded by technical jargon and inconsistent operator claims. This uncertainty can lead to costly errors and project delays, leaving you unsure if your investment in aerial data is genuinely reliable.

This definitive guide is designed to provide clarity and peace of mind. We will demystify the essential metrics, from Ground Sample Distance (GSD) to Root Mean Square Error (RMSE), and explain the technologies like RTK and PPK that separate hobbyist results from professional, survey-grade data. By the end, you will understand the key standards and be equipped to confidently specify project requirements, choose a qualified CAA-certified operator, and make critical decisions based on precise and verifiable aerial intelligence.

Key Takeaways

- Understand the critical difference between relative and absolute accuracy to correctly specify the data requirements for your project from the outset.

- Learn how technologies like RTK, PPK, and Ground Control Points (GCPs) are the essential components for achieving verifiable, survey-grade precision.

- Mastering key operational factors, from flight planning to weather conditions, is fundamental to meeting professional drone survey accuracy standards on every project.

- Ensure your projects are compliant by aligning your drone survey outputs with established UK benchmarks, including guidance from RICS and PAS 128 specifications.

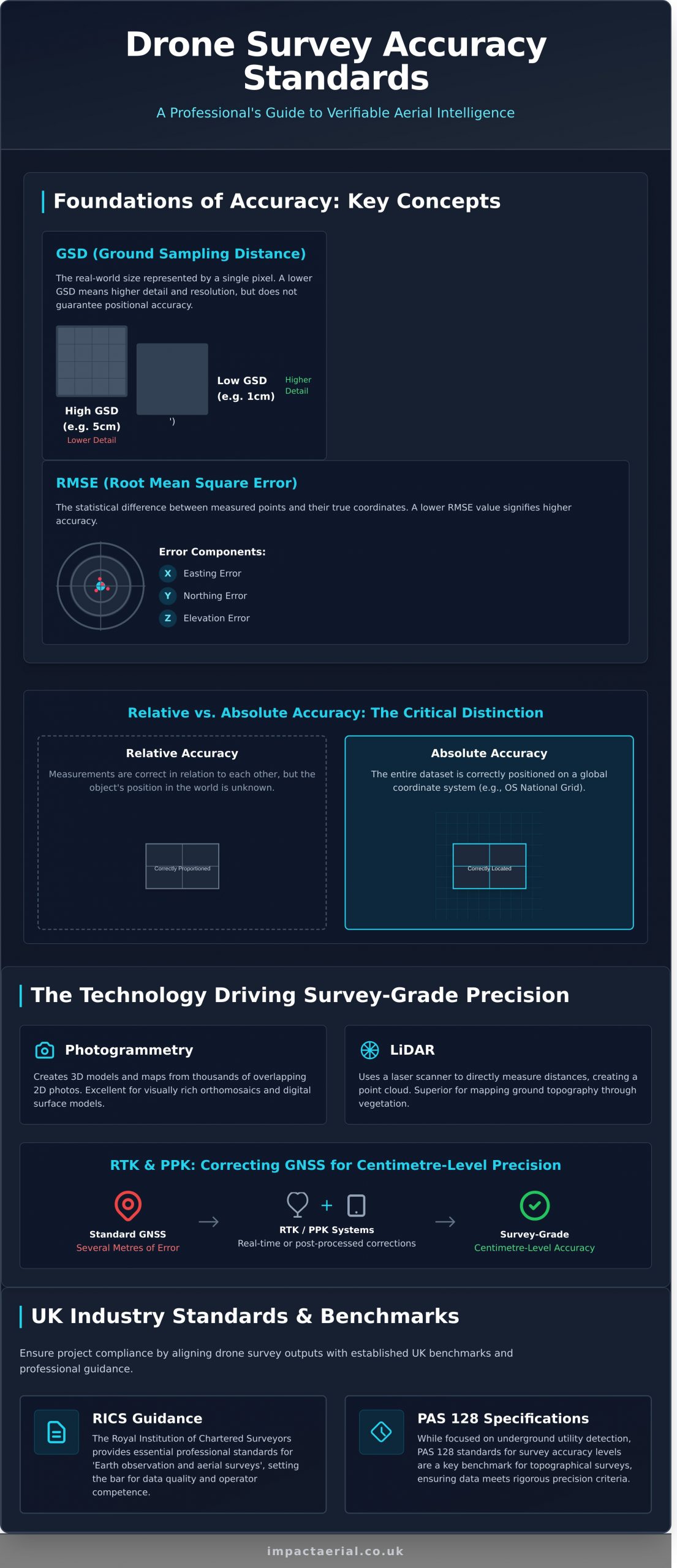

Foundations of Accuracy: Key Concepts in Drone Surveying

In a geospatial context, ‘accuracy’ is a precise, technical term. It moves beyond the subjective quality of a clear image to the objective, measurable precision of the data gathered. For project managers, understanding this distinction is crucial for evaluating the quality and reliability of a drone survey. It ensures that the final outputs-be they 3D models, topographical maps, or volume calculations-are not just visually impressive, but are built on a foundation of verifiable data. This section demystifies the core metrics and language that define professional drone survey accuracy standards.

To better understand these concepts in practice, the following video provides a clear overview of how survey accuracy is proven:

GSD (Ground Sampling Distance): The Building Block of Detail

Ground Sampling Distance is the real-world size represented by a single pixel in your aerial imagery. This value is determined by the drone’s flight altitude and the camera’s sensor and lens specifications. A lower GSD, such as 1cm, means each pixel covers a smaller area, resulting in a sharper, more detailed map. It is important to note that while GSD is fundamental to the resolution of your data and underpins the principles of photogrammetric surveys, it does not in itself guarantee positional accuracy.

Relative vs. Absolute Accuracy: The Critical Distinction

This is a critical concept in surveying. Relative accuracy means that measurements within the dataset are correct in relation to each other. For example, a survey could produce a perfectly proportioned floorplan of a building, with all wall lengths and angles correct. Absolute accuracy, however, means the entire dataset is correctly positioned on the Earth’s surface. Using our example, this would mean that the perfectly rendered floorplan is also placed in the correct location on a global coordinate system like the OS National Grid.

Understanding RMSE (Root Mean Square Error)

Root Mean Square Error is the industry-standard metric used to quantify the overall accuracy of a survey dataset. It represents the statistical difference between the coordinates of measured points and their ‘true’ known coordinates, established by ground control points. A lower RMSE value signifies higher accuracy. This is typically reported in three dimensions, giving you a clear, quantifiable measure of data quality:

- X Error (Easting)

- Y Error (Northing)

- Z Error (Elevation)

The Technology Driving Survey-Grade Precision

Achieving centimetre-level accuracy with a drone survey is not accidental; it is the direct result of combining specialist hardware, meticulous flight planning, and robust data processing techniques. While a standard consumer drone can capture impressive images, it lacks the sophisticated systems required for survey-grade data gathering. To meet professional drone survey accuracy standards, operators utilise a suite of integrated technologies. These systems work in concert to elevate a drone from a simple aerial camera into a powerful geospatial tool, a principle detailed in the official Earth observation and aerial survey standards from the Royal Institution of Chartered Surveyors (RICS).

Photogrammetry vs. LiDAR: Choosing the Right Sensor

The primary data capture is performed by one of two sensor types. Photogrammetry is the science of creating highly detailed 3D models and maps from hundreds or thousands of overlapping 2D photographs. It is exceptionally effective for creating visually rich orthomosaic maps and digital surface models. In contrast, LiDAR (Light Detection and Ranging) uses a laser scanner to fire rapid pulses of light, directly measuring distances to create a point cloud. Its key advantage is the ability to penetrate vegetation, making it the superior choice for accurately mapping ground topography in wooded or overgrown areas.

RTK and PPK: The Game-Changers for GNSS Positioning

A drone’s standard GNSS (Global Navigation Satellite System, which includes GPS) receiver has an inherent positioning error of several metres. To correct this, professional survey drones are equipped with either RTK or PPK systems.

- RTK (Real-Time Kinematic) uses a fixed ground base station to transmit live positioning corrections to the drone during flight, refining location data to within 1-2 centimetres.

- PPK (Post-Processed Kinematic) records satellite and drone data separately, which is then corrected against base station data after the flight.

Both technologies dramatically improve positional accuracy and significantly reduce the number of Ground Control Points required on site.

Ground Control Points (GCPs) and Checkpoints: The Ultimate Verification

Even with RTK or PPK, physical ground-truthing is essential for guaranteeing absolute accuracy. Ground Control Points (GCPs) are clearly marked targets placed across the survey area with their precise coordinates measured by a survey-grade GNSS rover. This data is used during processing to anchor the entire drone dataset to the real world. In addition, Checkpoints-which are identical to GCPs but are not used in the initial processing-serve as an independent means of verifying the final accuracy of the model. A professional survey report will always detail the GCPs used and the final accuracy results measured against these independent checkpoints.

Factors That Influence Drone Survey Data Quality

Achieving centimetre-level accuracy with a drone survey is not an automated process; it is the result of meticulous planning and professional control over numerous variables. Understanding these factors helps clients appreciate the technical skill required to produce survey-grade data and allows for better project planning to meet stringent drone survey accuracy standards. A professional pilot actively manages these elements to ensure the final deliverables are reliable and precise.

Flight Planning and Execution

The foundation of any reliable survey is a comprehensive flight plan. This mission-critical phase dictates the quality of the raw data captured. Key considerations include:

- Image Overlap: A high overlap, typically 70-80% both frontally and sideways, is crucial. This redundancy ensures photogrammetry software has sufficient common points between images to accurately reconstruct the 3D model.

- Flight Altitude: This determines the Ground Sample Distance (GSD)-the real-world size of one pixel in an image. A lower altitude yields a smaller GSD and higher detail but takes longer to cover an area. We balance this to meet project specifications efficiently.

- Flight Pattern: For flat, open land, a consistent grid pattern is effective. However, for complex sites with vertical structures or significant elevation changes, a crosshatch pattern (flying the grid twice, perpendicular to the first flight) is essential to minimise data gaps and building lean.

Throughout the flight, maintaining a consistent speed and fixed camera settings (aperture, ISO, shutter speed) is vital to prevent data inconsistencies that can compromise the final model.

Environmental and Site Conditions

A professional operator must assess and mitigate real-world site conditions. Weather is a primary concern; high winds can affect the drone’s stability and cause image blur, while poor or inconsistent light from fast-moving clouds can degrade image quality. Beyond the weather, site-specific features like dense vegetation can obscure the true ground level, while reflective surfaces such as water, glass, or wet asphalt can create errors and holes in the 3D data.

Equipment and Sensor Quality

The quality of the final data is fundamentally linked to the quality of the equipment. Consumer-grade drones are not built for the demands of professional surveying. For reliable and repeatable results that meet UK drone survey accuracy standards, professional-grade equipment is non-negotiable.

- Professional Drones: Platforms must offer superior stability, flight endurance, and often RTK/PPK capabilities for centimetre-level georeferencing.

- Camera Sensor: A larger sensor with a mechanical shutter produces far better results. Mechanical shutters prevent the ‘rolling shutter’ distortion common in consumer drones, which is critical for creating accurate orthomosaics and 3D models.

- Regular Calibration: Ensuring the camera and Inertial Measurement Unit (IMU) are regularly calibrated is a core part of professional operations, guaranteeing the system performs as expected.

For added peace of mind, our CAA-certified pilots use state-of-the-art professional drones, selected by Impact Aerial, to ensure we capture the highest quality data for every project.

UK Industry Standards and Accuracy Benchmarks

While the principles of photogrammetry are universal, their application within the UK construction, engineering, and property sectors is governed by established professional frameworks. Understanding these UK-specific drone survey accuracy standards is crucial for ensuring that the data you receive is not just technically precise, but also legally compliant and fit for purpose within a professional context.

RICS Guidance on Aerial Surveying

The Royal Institution of Chartered Surveyors (RICS) provides an essential professional framework for survey data. Their guidance on aerial surveying using drones emphasises the importance of a clearly defined project specification, transparent methodology, and comprehensive accuracy reporting. RICS standards focus on ensuring the final deliverables are reliable and meet the client’s specific needs, positioning drone-captured data within the same rigorous context as traditional survey outputs.

Applying Accuracy Classes to Your Project

The required level of accuracy is dictated entirely by the project’s goals. A professional operator will tailor the data-gathering process to meet these specific benchmarks. Common examples include:

- Topographic & As-Built Surveys: For site plans, design, and verification, an absolute accuracy of 2-5cm is the typical industry requirement. This demands the use of a robust GCP network.

- Volumetric Calculations: When measuring stockpiles or earthworks, high relative accuracy is the priority. The focus is on ensuring the internal consistency of the 3D model to produce reliable volume reports, often to within 1-2% of traditional measurements.

- Visual & Thermal Inspections: For asset condition reports, absolute positional accuracy is less critical than the Ground Sample Distance (GSD). A low GSD ensures high-resolution imagery where fine details like cracks or defects are clearly visible.

The Role of CAA Certification in Ensuring Quality

Technical skill must be paired with proven regulatory compliance. In the UK, any commercial drone operation is legally required to be conducted by a pilot holding a valid certification from the Civil Aviation Authority (CAA), such as the GVC (General VLOS Certificate). This certification is a non-negotiable standard that demonstrates a pilot’s operational competence, safety awareness, and understanding of UK airspace regulations. Working with a CAA-certified operator provides peace of mind that your survey is being conducted legally, safely, and professionally. To discuss how our fully certified services can meet your project’s accuracy needs, please contact our team of experts.

Partnering for Precision: Your Next Steps in Drone Surveying

Navigating the complexities of drone surveying in the UK requires a firm grasp of the principles that define data quality, from understanding Ground Sample Distance (GSD) to appreciating the transformative impact of RTK technology. Ultimately, adhering to professional drone survey accuracy standards is not merely a technical exercise; it is the fundamental requirement for delivering reliable, actionable data that project stakeholders can trust. The difference between acceptable and exceptional results lies in the combination of advanced equipment, meticulous planning, and certified operational expertise.

At Impact Aerial, we provide this exacting level of service for projects across the UK. Our CAA GVC Certified and fully insured pilots leverage professional DJI Enterprise drones with RTK capabilities, bringing extensive experience from demanding construction, property, and infrastructure sectors. Ensure your project’s success with verifiable, survey-grade data. Contact Impact Aerial for a consultation. Let us provide the precision and peace of mind your critical projects deserve.

Frequently Asked Questions About Drone Survey Accuracy

What is a realistic accuracy I can expect from a professional drone survey?

For a professionally executed drone survey utilising RTK/PPK technology and a robust network of Ground Control Points (GCPs), you can realistically expect accuracies in the range of 1-3cm horizontally and 2-5cm vertically. This level of precision is well within the tolerances required for most topographical mapping, construction progress monitoring, and volumetric calculation tasks. The final accuracy is always dependent on the project specification, equipment used, and the methodology applied by the certified drone operator.

Is a drone survey as accurate as traditional ground-based surveying methods?

Yes, for many applications, a high-quality drone survey can achieve accuracy comparable to traditional ground-based methods like GPS rovers or Total Stations. For large-scale topographical surveys, drone photogrammetry is often more efficient while delivering similar centimetre-level results. However, for specific high-precision tasks, such as establishing primary site control or deformation monitoring, traditional survey techniques remain the benchmark. The key is choosing the right tool for the specific project requirements.

If a drone has RTK/PPK, are Ground Control Points still necessary?

While RTK/PPK technology significantly improves the positional accuracy of the drone’s camera, we strongly advocate for the use of Ground Control Points (GCPs) as an essential quality assurance measure. GCPs provide an independent ground-truth reference that verifies the absolute accuracy of the final dataset. For projects where precision is critical and data must be defensible, using a combination of RTK/PPK and GCPs is the professional standard and ensures the highest level of confidence.

How can I verify the accuracy of the drone survey data I receive?

The most direct method is to review the comprehensive survey report provided by your drone services provider. This document should detail the Root Mean Square Error (RMSE) calculated from the Ground Control Points and independent Check Points. For added peace of mind, you can use a GPS rover to check the coordinates of several distinct features (e.g., manhole covers, building corners) on-site and compare them directly against the coordinates in the delivered 3D model or orthophoto.

What key information should be included in a drone survey accuracy report?

A professional accuracy report should be transparent and detailed, adhering to recognised drone survey accuracy standards. Key information must include the coordinate system used (e.g., OSGB36), the number and distribution of GCPs and Check Points, and a clear table showing the Root Mean Square Error (RMSE) for the X, Y, and Z axes. It should also contain a summary statement confirming the final achieved accuracy and its fitness for the intended purpose of the survey data.

Does the accuracy of a drone survey affect its cost?

Yes, the required level of accuracy is a significant factor in the overall cost of a drone survey. Achieving higher, centimetre-level accuracy necessitates more extensive fieldwork, including the placement and measurement of multiple Ground Control Points by a surveyor. It also requires more sophisticated RTK/PPK-enabled drones and longer data processing times. A survey for visual progress monitoring will cost considerably less than one required for precise as-built verification, with prices potentially varying by hundreds of pounds (£).